CBD, CBD, CBD, and more CBD. It seems that everyone is talking about cannabidiol (CBD), but where does it come from and how do we get it? Cannabidiol (CBD) and other cannabinoids are molecules that come from the cannabis plant (hemp or marijuana). Cannabinoids are used in a wide variety of products ranging from topicals to edibles to smokeables and even to products for pets. In these products, the consumer finds CBD isolate or full spectrum CBD or broad spectrum CBD. These are all extracts from the hemp plant. So how do manufacturers actually extract the CBD and other cannabinoids from the physical plant? There are several methods, some more costly than others, some more dangerous than others, and some produce a higher quality product than others.

Extraction Methods

Carbon Dioxide (CO2)

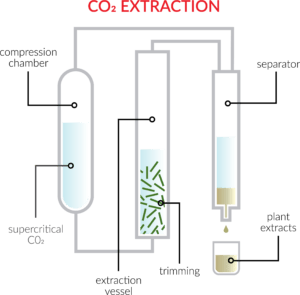

Carbon dioxide extract is a method used by many reputable CBD extractors. The process is safe, creates a potent and high quality product that, unlike other extraction methods, is free of chlorophyll which can leave a bitter taste. The extraction takes place in three (3) steps in a closed-loop system, as pictured in the figure below. A closed-loop system means that there is feedback so that the end of the process leads back to the start in a cycle (or a loop).

- First, the CO2 in the compression chamber is cooled to -79 °F and pressurized to create supercritical CO2. Supercritical refers to a state of being both a liquid and solid.

- The supercritical CO2 is pumped into the extraction vessel containing the plant material. This process separates the cannabinoids, terpenes, and trichomes from the plant material.

- The final step occurs in the separator. Here, the CO2 evaporates from the extraction and cycles back to the compression chamber. What is left is the plant extraction.

The downside of this extraction method is how costly it is and how complicated the process can be to properly run.

Dry Ice

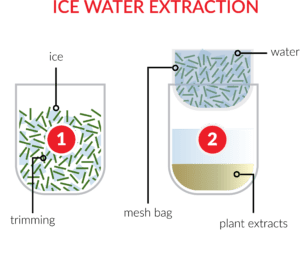

Extraction using dry or regular ice is similar in process to creating “hash” or “bubble hash”. The result is a powdery resin containing cannabinoids from the cannabis plant. This method is inexpensive, has a high yield, and delivers a clean, solventless product. On the flip side, it can be impractical in terms of the extensive labor and time required that could result in a sub-par extract. The process occurs in three (3) steps as pictured in the figure below:

- To begin, ice and plant material are mixed to aid in separating the trichomes and cannabinoids from the actual plant.

- Water is then added and the mixture is strained through progressively smaller micron mesh bags. This process is repeated until the best quality product is remaining.

- Finally, water is drained from the extract and then left to dry out. The result is a clean resin.

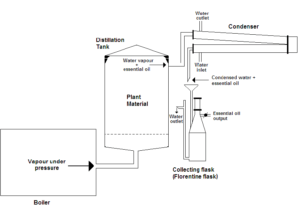

Steam

Using steam is a tried and true method of CBD extraction. Unfortunately, it is quite inefficient, relatively more difficult, and risky in terms of damaging the plant material. Steam is passed through the plant material to separate the oil vapors containing cannabinoids from the plant. Condenser tubes create a mixture of oil and water. This mixture is distilled (made more pure) leaving only the cannabis extract. The figure below pictures the process.

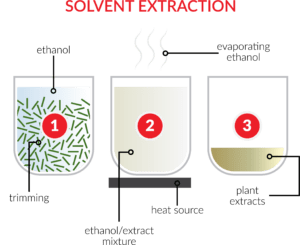

Solvent

Maybe the most common method of extraction is using solvents such as butane, propane, ethanol, or isopropyl. This method is inexpensive, fast, and easy. But it is also the most dangerous method because the solvents used are highly flammable. This method also has a risk of the end products containing some undesirable residual solvent. The solvent is passed through the plant material, allowing it to pick up and extract cannabinoids from the plant. The solvent is then evaporated leaving only the cannabis extract. In addition to extracting cannabinoids, chlorophyll is also extracted and this could give the end product a bitter taste. The figure below shows the extraction method.

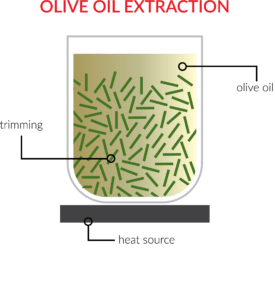

Olive Oil

Using olive oil to extract cannabinoids from the cannabis plant is more an at-home method for cannabis enthusiasts than a method used by legal manufacturers. The end results is a combination of olive oil and cannabinoids, meaning it is much less concentrated than other extractions and therefore requires more to be ingested to experience benefits. On the plus side, it is a safe, inexpensive, and simple process that takes just two (2) steps as pictured in the figure below.

- First, the plant material must be decarboxylated to activate the cannabinoids. To do this, the plant should be heated to about 250 °F and left to sit for between 30 and 60 minutes.

- Next, the plant material is mixed with olive oil and reheated for about two (2) hours, allowing the fats in olive oil to extract the cannabinoids from the plant material.

Which is Best?

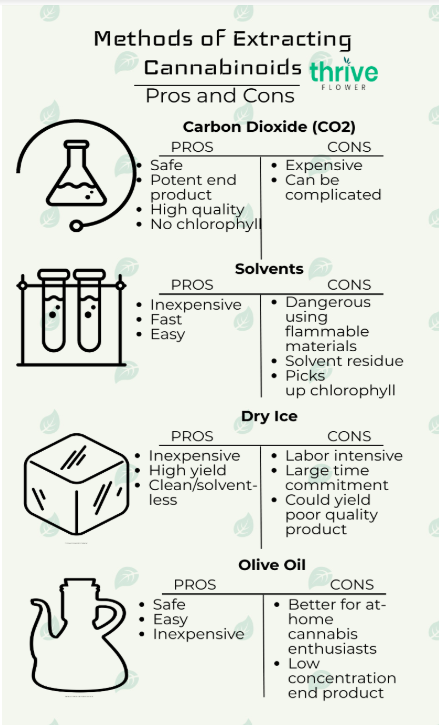

Each extraction method has pros and cons as pictured in the infographic below. It is thought by many that using CO2 is the best method because it consistently produces a high quality product that is safe from any neurotoxin contamination (meaning it is a clean extract). Although it is the most expensive method, it is a small price to pay to bring quality and clean products to the consumer. If you ever have questions, reach out to the company and they should be able to provide you with a direct and honest answer.